BAL-AMi Jukeboxes - A Brief History

The history of BAL-AMi jukeboxes spans only around 11-12 years, from 1951 to 1962. For the most part the jukeboxes that were manufactured were derivatives of those produced by AMi (Automatic Musical Instrument Company) of the USA, and made under licence. However, around half of the models produced used the basics of the USA designs to produce smaller units for the UK market.

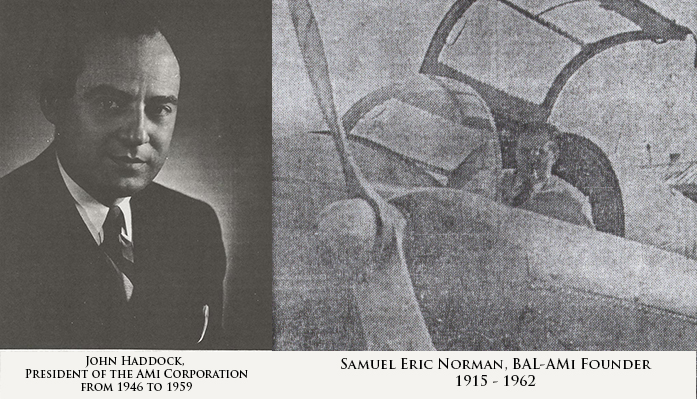

In 1951, import restrictions in the UK determined that manufactured goods from abroad could only be sold in the home market if at least 53% of the content was British made. Samuel Norman (born Ilford 1915), of the Balfour (Marine) Engineering Company based at 290/296 High Road, Ilford, Essex, saw an opportunity to build jukeboxes in the UK using existing American designs. He met John Haddock who ran AMi at that time and set up an agreement to import some of the AMi components, whilst manufacturing others in the UK. These parts would be used to build AMi designed jukeboxes under licence. The UK machines would be called BAL-AMi.

Balfour House in 2015 - now apartments and shops

Whilst the first machines to be shipped from the Ilford factory were the 'D' and 'E' models, the BAL-AMi name was not used until the G80 of 1955, priced at around 625 UKP. The model 'F' was never made in England, although evidence exists that some 'F' machines were converted to 240v in Australia, had a Beam Echo amp installed, and then had the BAL-AMi name added. The background to these machines is not entirely clear.

The most popular (in terms of numbers) BAL-AMi jukeboxes were the 1956 Junior and the 1958 model 'I'. Both were manufactured at the BAL-AMi factory in Ilford, with some cabinets made in the Balfour Harlow (Essex, UK) facility. The I200s were mostly in manual select format (the USA AMi version was widely available with electric select). Some BAL-AMi I200 electric select machines do exist, but these seem to have been made in very small numbers, with less than ten survivors known to exist. The UK BAL-AMi I200 was manufactured almost entirely in the pink/charcoal configuration, but some turquoise examples do exist, albeit with a pink cap (which makes them look very odd). The American version came in both pink and turquoise (with a turquoise cap!)

Perhaps the biggest innovation during the BAL-AMi era was the production of a range of scaled down jukeboxes to address the needs of smaller UK locations. These used 40-selection mechanisms and were known as the Junior 40, Super 40, and Super 40 Deluxe, and were built between 1956-1959. The J40 was a design based upon the model 'F' using some parts from the model 'G' !

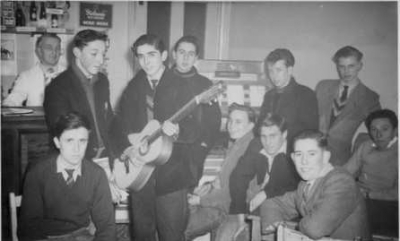

Typical coffee bar jukebox location in the 1950s. This is the Rose Café in South Croydon, November 1957, with a BAL-AMi G80 in the corner. Photo courtesy of Clive Poge - standing next to the juke on the right!

By 1956, demand had substantially increased, and an additional factory in Harlow, Essex (just north-east of London) was purchased by Balfour for production of cabinets for the 'G' models. Production and assembly remained at Ilford.

BAL-AMi did not clone every AMi jukebox during this period. The most notable absentees were that of the AMi model 'H' and the Continental. Perhaps the departure in AMi design that came with these models was too much of a shock for Balfour!

They did, however, continue the design ethos of the 'H' and 'I' into the 1960's with the Super 100 model. This shared many visual features from the model 'I' and even used the glass windscreen from the 'H'. Many of these machines that survive have since been converted to 200 selection jukeboxes.

Balfour also seem to have invested in some sort of production facility in Le Touquet, France, to manufacturer and distribute jukeboxes for continental Europe. The detail of this facility is not fully understood, but there is clear evidence of a unique model (the "Century") being produced, and recollections from former employees confirm that regular trips were made by colleagues over to Le Touquet.

In the early 1960's, a number of import restrictions were lifted and BAL-AMi found themselves competing to sell the 'J' and 'K' models against the American AMi versions being sold by other UK agents. Wurlitzers, Seeburgs and Rock-Olas were also now free to enter the country.

What turned out to be the last model built by BAL-AMi was the New Yorker. This was a hotch-potch of a machine using parts from the model 'K' and the front grille and star from the mark one Continental.

Samuel Norman died in March 1962 of leukemia aged only 47. Details of what became of the jukebox operation at Balfour after this are sketchy. Around about the same time, the AMi corporation in the USA merged with Rowe, creating an even more powerful competitor. Whatever the circumstances, a decision was taken to cease jukebox production for good. A sad end to an exciting 12 years !

As well as continuing to make spares for BAL-AMi jukeboxes, the engineering side of the company continued to manufacture record players, ice cream machines, and aircraft engine parts for Rolls Royce, including turbine blades for Concorde. They were also heavily involved in work for the TSR2 fighter aircraft, but that was cancelled by the Government of the day in favour of the American F111 swing wing fighter. Balfour eventually closed its doors for the last time in the early 1970s.

(With thanks to Tony Holmes, Terry Lovell , and Keith Hutchinson for much of the information contained in the above article.)

How much of a BAL-AMi jukebox was "Made in Britain" ?

As an addendum to the above short history, a visitor to this web site, John Adams, has written a very interesting article analysing the British content of a G80:

BAL-AMi G80 - How Much of it is British?

Much has been documented about the BAL-AMi, and it's a well known fact that they were a licensed product, built on the base and reputation of the established American company, Automatic Musical Instruments. It's also fairly well known, that the main reason for creating the partnership of a British manufacturer, together with an American one, was compliance with import restrictions, in force due to the need for recovery from both physical and economic damage from the (then) recent war.

But, has anyone, more than casually, observed the differences between the original AMi and the British counterpart models? In this study, I've taken the G80, the first to carry the BAL-AMi badge, as the subject. Closer investigation reveals more British manufactured components than you might imagine.

The cabinet is obviously going to be made in Britain. Starting at the top, with the externally defined horn, differences can be seen. Early models of the G80 sported a wooden trim, holding an anodised, fine mesh, aluminium grille around the edge of the top mounted horn. Obviously a home product, as the American original was trimmed with a chrome plated casting, and an AMi badge in the centre of the plated grille.

Later BAL-AMi models carried a similar casting, not an imported one, and there were obvious differences. The BAL-AMi badge, requiring differently spaced fixing holes, and the square punched holes in the plated grille, were slightly larger. Looking at the original flyer for the G, (see the advertising page on this web site), around the wooden horn trim and cast horn trim, there's most of the variants shown, implying that there was little, actually ready to market at the time of preparation. Close inspection shows that the emberred charcoal one, without the badge, doesn't even have an inner trim fitted!

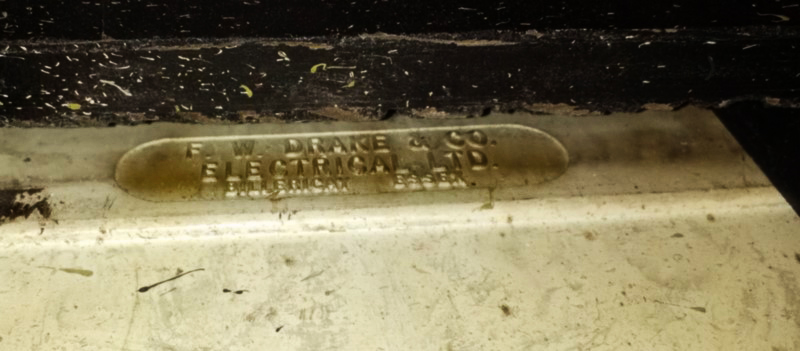

Inside the casing, a horn manufactured by E.W. Drake of Billericay, Essex, could be found, with a Goodmans of Wembley, Middlesex, compression driver connected to the throat. The American driver was sourced from Electrovoice.

Casting the eye downward immediately reveals a different font, to the American market's Multi Horn High Fidelity logo. Also immediately noticeable is the fact that the side glass doors are smaller - another home product, or was this to use up an overproduction of doors for the model F?

Looking past the glass, onto the actual mechanism, this is obviously an American AMi casting (at this point in the production history), supporting what initially looks like the complete American unit, but look closer. Firstly the pick up arm is different. In fact, incorporating a counterbalance weight. In terms of record care, this is a better one than that fitted to the American product. It appears to be a cosmetically updated version of the arm fitted to the models D and E. It's fitted with a Tannoy cartridge made by the highly reputed West Norwood based company. Closer visual scrutiny reveals it's a one piece turntable mechanism cover, unlike the American original, which has removable panels, secured by visible screws. Underneath is a motor made by Collaro, of Barking, Essex, The surrounding trim, together with the chequered waterslide transfer is more than likely locally sourced. And isn't that green dome, over the selection indicator light, different to the one from Grand Rapids?

Looking at the door below, the cast trim and fittings are identical, except for the grille and lock. Mesh grilles varied, so would probably have come from various suppliers, most likely based in Essex. However, the lock appears to be the furthest travelled British component being from Union of Willenhall. They appear to have been the main supplier of locks.

Opening the door reveals a British amplifier by Beam Echo, but we all knew that, didn't we? Made in Witham, Essex. I think there's also a strong possibility that the crossover network was also manufactured in England, as there is a marked difference in that there's a wire wound attenuator, to balance sound levels between speaker drivers, not seen in the American built units. The 12” bass speaker, inside that cover behind the amplifier, is an Audiom, another Goodmans product.

So, judging by the pictures of the factory, available in another article, all of the looms were made in the Balfour facility, and would have used British cable. Fluorescent light fittings, tubes, starters etc, falling into the category of sundries, would have come from local suppliers.

All in all, it looks as though more than 53% was made in Britain. That seems to make Sam Norman look like quite a shrewd businessman.

Or, prompted by the revelation of “The best kept secret in the business”, back in May, 1961, it could be speculated that Sam might have been somewhat more shrewd than those at Ami, who had awarded him the contract.

On the other hand, Sam Norman was soon building and successfully selling some of his own similar looking machines These had less glittering trim, utilising an exclusive combined amplifier and power supply unit, delivering around 15 watts sound output, hence requiring lower power speakers. All of these factors reduced manufacturing costs and selling prices. Small wonder that the name BAL-AMi was displayed on about 80% of jukeboxes in the U.K., outselling the American counterparts, but still bearing the AMi name. Obviously the contract allowed this, but in 1961, with its incredibly square appearance, blatantly suggesting low production cost, was the New Yorker the last straw?

It is widely believed that a five year contract simply ran out. If this was the case, why was the following statement issued to the press by Balfour in May 1961:

“We are pleased to announce that an agreement has been concluded for the sale by Balfour (Marine) Engineering Company Ltd., and Automatic Musical Instruments (Great Britain) Limited, of their joint interests in the phonograph industry to the Rowe Automatic Merchandising Company Ltd., which company, like AMi, is a member of the Automatic Canteen Group. The sale involves a substantial payment for stocks of spares, tools and goodwill.”

But, what about the rest of the world? There has been some speculation about the number of BAL-AMi models, usually G120s, found in Australia and New Zealand.

There are some pointers towards conjecture, on the “Literature” page, there is a drawing shown, detailing production of the American style pick up (Tone) arm.

Louis Ward comments that he worked on these, in Worcester. It had been assumed that these were imported.

Also, on the same page, is a news item, “How it's Done” featuring a photo of the large milling machine, used for milling base castings.

Again, it was assumed that these were another imported item.

Did that contract, contain wording, possibly by default, permitting the franchise to include the British Commonwealth countries?