Behind the BAL-AMi Factory Gate

Given that BAL-AMi stopped making jukeboxes in 1963, the number of people that were involved in their manufacture is dwindling as time goes on. This page records the memories of some of those employees.

If you worked at the BAL-AMi factory, or maybe knew someone who did, drop me a line. Some names I've come across are:

Tony Fahy, Ken Calvy, Tom Maher, Irene Goodwin, Roy Pipfer, Len Burton, and Ronnie Palmer.

Harry Lovell, on the left, unloading a Model G at Music Hire in Leeds. Harry's son Terry has contributed to this web site and runs a jukebox business to this day.

Some photos from within the BAL-AMi factory:

Tony Fahy building a Model G cabinet

Roy Pipfer assembling a record playing mechanism

Len Burton testing the record playing mechanism

Ronnie Palmer, above and below, in the final assembly area

Ken Calvy ,on the right, making jukebox cabinets

Tom Maher assembling a loudspeaker enclosure

Irene Goodwin making wiring looms

Norman Jones

Norman Jones, a retired electrical engineer, now living in Berkshire, was an apprentice at the BAL-AMi factory in Ilford from 1958-61. He recalls,

"I knew Sam Norman, he was the step father of a school friend of mine at the time, called William. Sam was married to Elsie, William's mother.

Sam gave me an early working break and offered me an apprenticeship at Balfour Marine Engineering in Ilford, where I worked for three years, during which time I assembled, installed and maintained BAL AMi jukeboxes. I was also involved in setting up the factory in Harlow, which was opened to allow for the expansion into electronic “bar bowls” and the conversion of US manufactured AMi Jukeboxes. This involved changing the power supply input and the coin mechanisms. We also had to modify the turntable motor to allow for the different mains frequency in the UK.

I have recollections about Sam and his business exploits, including the gallons of orange juice he once purchased and filled the main entrance hall of the factory in Ilford, at a time when there was a national shortage of orange juice, which I think was caused by problems with the crop in Brazil. Also his associations with Bill Larkin of Larkin's peanuts. I remember being in hospital for a while and Bill Larkin coming to see me with enough peanuts and coconut ice bars to feed the hospital for days.

Another character to remember was Wilf, who I think was Sam's brother-in-law. He was general manager of the Ilford factory and had a desk in the main entrance where he could see all the comings and goings of people and materials.

I was older than William and passed my driving test some months before him. Whilst Sam was abroad in Le Touquet, William and I would be off in his gold Bentley Convertible, with me driving. This was unknown to Sam of course, but with Elsie’s agreement. On one occasion I had dropped William off to go into Boots in Walthamstow and was driving around the block several times before being waved down by a policeman, who wondered what a young lad was doing driving a £40,000 motor car. The policeman showed a lot of interest in the car and before long we had the bonnet open.

We thought nothing was going to happen, but just as we were driving away, the policeman said he wanted to see the insurance certificate!!!! That was going to be difficult because it was in the company safe back in Ilford and only Sam and Wilf had the combination. However, Wilf was great and helped us out of the jam.

On another occasion, I was driving Elsie's MGA, and smashed up the front wing. Returning to Sam's house in Chigwell, he was leaning against the fireplace as we entered the lounge. Instead of the rollocking we expected, Sam said "hello Hoppy, looks bloody untidy with one wing smashed, take it back out and match up the other side!!"

(He always called me Hoppy because of the limp I had from the polio I had when I was twelve years old)

At our look of surprise, he said "if you don't, you might lose your driving confidence".

That was the sort of guy he was.

I also got to drive Sam's Ferrari around the Walthamstow Greyhound Stadium car park. Got up to about 50 mph without touching the accelerator. It was awesome. I have seen Sam leave the factory in Ilford in the Ferrari and drive a couple of hundred yards on the wrong side of the road to get into a gap in the traffic, well ahead of him! Wow, that was some machine!

Another character I knew well and we had plenty of laughs together was Eddie. He was a general handyman (only he was about my age,19) and came out with me when we did the installations to help with the lifting etc. I was not able to carry the heavy stuff. We did the installation of the Hideway unit at the Thatched House pub in Epping. What a laugh that was, trying to get the machine down into the beer cellar.

It was a very cut-throat business, with people trying to sabotage machines using washers, foreign coins and even iron filings in the coin mechanisms. If the machines were not bringing in the money and the customers, then the coffee bars and pubs would want them out and replaced with a competitors machine.

I looked after about twenty installations around the east end of London and Essex. They ranged from the smoky cafés in Bethnal Green to the Thatched House pub in Epping. I made regular visits to empty the coin boxes and change the record selections as appropriate. My pockets were always full of the centres of EPs!!!!!!!!

Each machine had a “times played" recorder and if a record was not playing much, it had to be changed. Staff were allowed to purchase the used 45s for a few pence, so it was tempting to add a record I liked to a collection on a machine that was not going to play it very much, and then change it a couple of weeks later!

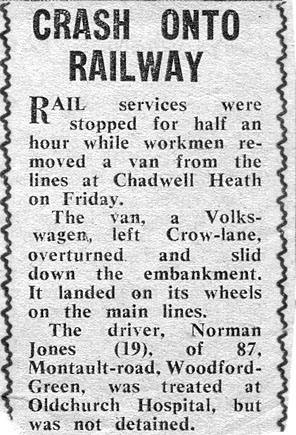

One other event that occurred whilst I was working at Balfour, was the accident I had in the company VW van, which caused some concern at the time as I rolled down a railway embankment and landed up on the lines in front of the Southend to Liverpool Street express. It's a wonder I got to 20 years old, let alone 67!

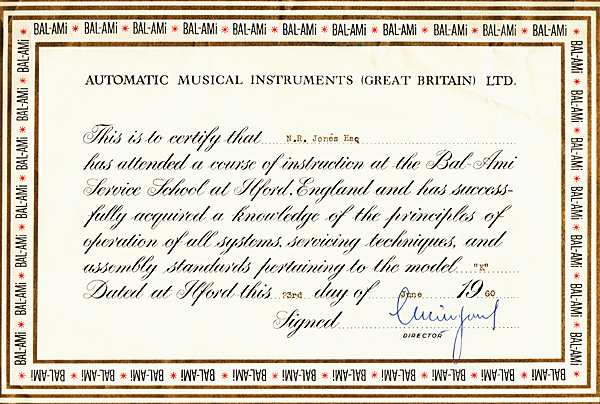

The image below is a certificate I received in 1960 following an in-house training course for the Model "K". You will notice that my certificate is signed by Cecil Jones, a director of the company.

Known to be a friend of the family and with my surname being Jones also, I was treated with some suspicion by the rest of the staff!!"

Norman is pictured here in 2008.

Julian Huxley

I used to work in the amplifier department in the 1950's and 60's when I was a teenager. I remember Sam Norman and visited his house many times - I lived just a couple of miles away from him. They were wonderful days and I can remember building my own first valve amplifier from various bits scrounged from our department!

After BAL-AMi stopped making jukeboxes, it started designing and manufacturing one-armed bandits. They did not last for very long and I was then involved in designing and building ice cream machines!!

It all became rather depressing after that and I left to pursue my passion for films and photography.

John Popplewell

I remember Balfour Marine many years ago, even before they built the new frontage around about 1956. Eric Cross and Dickie Dodkins played for the works football team, and I also got a chance to play one game with them.

Bill Larkin, Sammy Norman, Percy Dalton, and the Fish King from Billingsgate were like the Rat Pack 😃 . They had no fear of anything and got up to many pranks together.

My dad Dick Popplewell did carpentry work for all of them at different times, including folding teak garage doors and a huge staircase like a film set in Sammy's house in Manor Road, Hainault. Dad was instrumental in second fixing to the interior of the new frontage.

All four of them came to our house to take dad to a boxing match with one of Bill's employees. Somehow I got to go instead, the ring was by Mile End station. I felt like I was sitting with Royalty 😃.

Dad also did work in Bill's Factory in Leytonstone, and his shop in Barking. An experience of my life I will never forget. Happy times for sure.

Freddy Bailey writes:

I met Cecil Jones, who was the Managing Director of AMi (Great Britain) Ltd, several times with my father. He also owned a jukebox operating company called Acoustics Developments Ltd at 4 Denbar Parade on Eastern Avenue in Romford. He also was instrumental in setting up the Harlow plant to produce the Bally Jumbo gaming machines.

John Haddock, then President of AMi in the US, put the deal together for AMi (Great Britain) Ltd to build the Bally machines. The connection was that his big distributor in the US, Runyon Sales Company Inc. of New Jersey, put up the money for Billy O'Donnell to buy Bally in 1963.

Also I recently (2010) spoke to Ray Laren the son of Dave Laren, who was the partner of Sam Norman in the "Silver Queen" fruit machine venture. Ray told me that Sam had a brother who was a pig farmer. He also told me that he (Ray Laren) went to Balfour Marine Engineering Ltd to train how to fix the models G80, J40 and S100 models. He said that the Super Forty model was originally going to be the Super Sixty model but they could not get a layout right for the sixty buttons, so they made the Super Forty Mk II. I once remember seeing a Super Sixty cabinet at Music Hire Ltd in Leeds. If you look at the title strip panels you can see there is provision for 60 title strips.

My father bought the very first BAL-AMi Super 40 for 345 UK pounds brand new, we had it in our arcade at Mundesley-On-Sea, in Norfolk. The AMi G-200 was built into the same style cabinet as the G-120, and the mechanism was the forerunner to the AMi Continental that was a nightmare to operate.

BAL-AMi originally made a fruit machine for a short while, it was called Silver Queen. The tooling for that machine was later passed on to Bell-Fruit Manufacturing Ltd who used the tooling for their very first fruit machine called "Three-Alike" in 1960. BAL-AMi also made some Bally upright games under licence known as Bally Jumbo's.

Peter Redding has kindly sent a photo of a Silver Queen fruit machine that he now owns

Louis Ward - Balfour Planning Engineer and Design Draughtsman - 1951-59

I am indebted to Norman Leach for sourcing the following recollection from his cousin, Louis Ward, who was a draughtsman at the Balfour organisation - Ed

The Balfour Marine and Aviation Engineering Company, at the time when they were situated in the Ilford High Road, were eminent in the machining of aircraft components. The "marine" part of the company was not evident at this time. Components were produced in batch quantities, some from forgings which contributed to their strength and durability due to the grain flow of the metal thus achieved.

In some instances, the manufacture of components was insured at Lloyds of London against the risk of a false cut, possibly after some hundreds of man/machine hours of production, to limits of a few tens of a thousandth of an inch. The operators of the various machine tools involved in producing the components were guided in their operations by series of stage drawings, and added fixtures which were planned, designed and detailed by the Balfour planning engineers and design draughtsmen, one of whom was me.

Balfour Engineering were chosen to undertake this work by the foremost aircraft companies in Great Britain including D.Napier, A.V.Roe, BAC, and others whose illustrious names are now part of the history of aviation.

The production of jukeboxes by Balfour, which began during this time under licence from Associated Musical Industries (AMi) of the USA, was within the compass of Balfour Engineering and did not affect the manufacture described above.

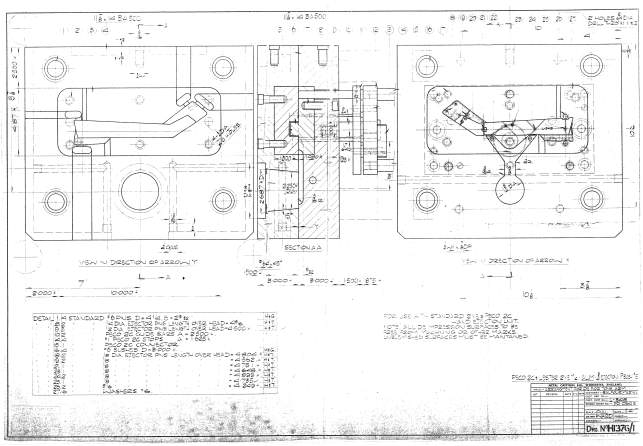

At some stage it was realised that moulds would be required for the quantity production of various parts such as the tone arm and mechanism, plus trims etc.. However, due to pressure of work on the specialist design and drawing office personnel at the Midlands offices of an associate company, Messrs Metal Castings of Worcester, this capacity was not forthcoming.

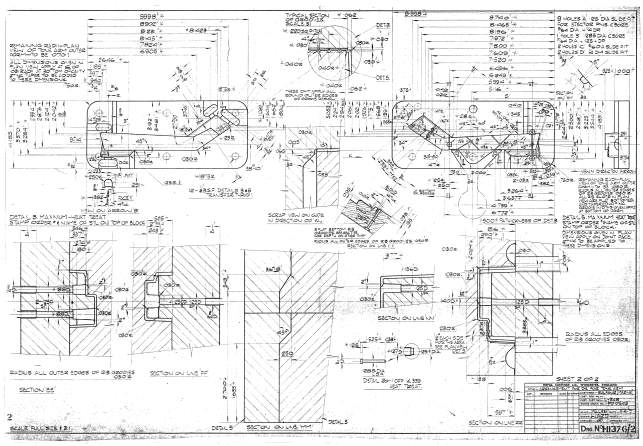

In this event, I was sent to live and work in Worcester to fulfill this requirement and was engaged there for several months. One of the zinc moulds designed and fully dimensioned for manufacture, namely that of the tone arm, is illustrated herewith (see below - Ed).

From Mark Hall:

I was an engineering apprentice at Balfour between August 1970 and May 1971, when I was made redundant.

As a first year apprentice I didn't really know exactly what Balfour were doing but as far as I am aware most of the work was machining aero engine components for Rolls Royce. It was the collapse of Rolls Royce in 1971 that led to the apprentices all being made redundant, and, I presume, the closure of the company.

Somewhere I still have a heavy stainless steel component which I was told at the time was a rejected aero engine part. I'm sure that one of the directors was a Mr (V?) Norman and he drove a sporty Ford Escort, probably a Mk1 Escort 1300GT, or maybe something more exotic and specially prepared for him by Ford, who were based a few miles away at Dagenham.

The training officer was a Mr Reg Pitman, who lived at Chelmsford and drove a Ford too, an Anglia I think. Chelmsford to Ilford was a long way to commute in those days. I remember one day Reg came into work with the gear lever still in his hand! His assistant, who kept a close eye on all apprentices, was Jock McClean. I recall Jock telling us about jukeboxes so I suspect he may have been there a long time.

From Russell Ward:

I worked at Balfour Marine Engineering in the late 1950's. I never saw the jukeboxes being made, it was too late. I was working as an apprentice tool maker and worked on the nose cones of jet fighters (can't remember the name, maybe Fairy Delta ). I remember having to rivet components around the diameter of these nose cones and often having to take them out again and replace then again due to not being in the right position (very fussy Rolls Royce !).

I do remember the one arm bandits being stored on the staircase of the reception area, a large wide spiral affair from top to bottom of the building. If I can remember rightly they were about to be shipped out somewhere.

I never met Sammy Norman but I remember seeing his son driving around Barkingside area where I lived in an AC Cobra and other fancy cars. Also if I remember rightly Sammy's house on the Manor Road Chigwell was one of the largest down there amongst all the other mansions.

I used to get on a bus at Barkingside and get off at Plessey's and walk over the Iron Bridge with my lunch pack to Ilford High Rd, fond memories indeed.

From Eddie Caswell:

I worked at Balfour Marine Engineering as an apprentice engineer from c.1955 to 1958, during which time I was taught the importance of precision, and respect for attention to detail, which I have valued ever since.

During my time at Balfour one of the tasks I enjoyed was to machine parts for BAL-AMi jukeboxes as work experience, which was great because we apprentices were able to earn extra money !

I made friends with another apprentice Mickey Collins, and we both shared a liking of modern jazz and visited places like The Flamingo in Wardour Street, in the west end of London, together with our girlfriends.

I remember having to cycle to work each day from Forest Gate.

From David Hearn:

I worked at Ilford from 1953 until 1960 at a time when just about every street corner had a small engineering works on it. But Balfour was something special with its engineers all being highly skilled craftsmen, all working to AID and ARB limits.

Balfour contracted for all of the main aircraft companies of the time. Ones that come to mind were A.V.Roe, Bristol, Napier, Foland, Vickers, and Shorts. They had three jig borers that could turn the large rings used on jet engines, plus an optical jig borer that had a room of its own.

It was on the first floor of the new office block that Joe Dawney had his workshop. Nobody knew what he was doing apart from tinkering with jukeboxes!

Sam and Les Norman were the owners, two very different people, but both big men.

Les looked after the administration. He was not very outgoing and owned a farm in Essex. He also flew a small twin engine plane.

Sam the playboy married one of the Chandler girls whose father owned the Walthamstow dog track. Sam was involved at one time with a man called George Dawson who was jailed for six years for an orange juice swindle. Wooden barrels of the concentrate stood in the Balfour materials yard for some weeks!!